Our Machine Safety Validation is the process of verifying and proving that all implemented safety measures function correctly and effectively reduce risks to an acceptable level. It ensures the machine, safety components, and control systems comply with industry safety standards and operate safely under real working conditions.

Our Validation Procedure

1.Compliance Documentation & Report

Provide official validation report and test certificates

2.Review of Risk Assessment & Safety Concept

Confirm safety requirements and performance levels

3.Functionality & Performance Testing

Validate that each protective device operates correctly and consistently

4.Failure Simulation & Response Testing

Test machine behavior in fault conditions (interlock break, gate open, etc.)

5.Measuring Safety Performance Level (PL / SIL)

Confirm performance levels as per ISO 13849-1 / IEC 62061

What Machine Safety Validation Includes

- Functional testing of all safety features

- Verification of interlocking systems

- Emergency stop system testing

- Validation of safety PLC and safety relay logic

- Light curtain & sensor response tests

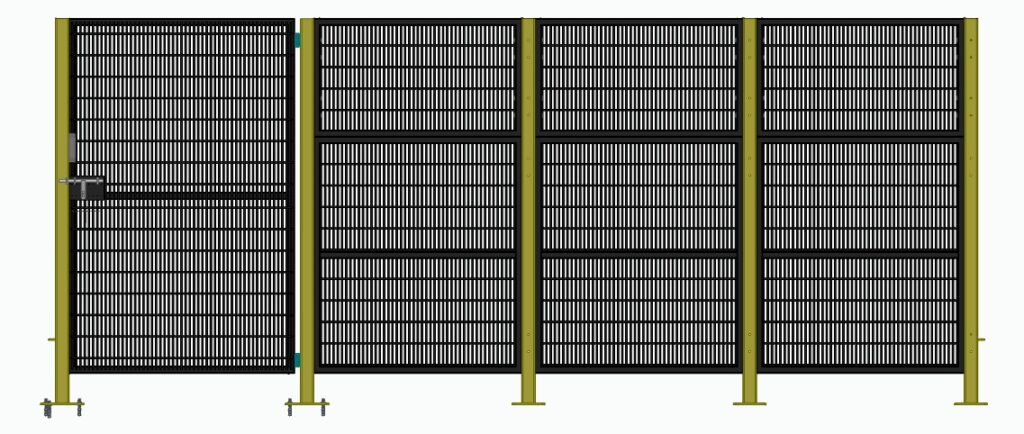

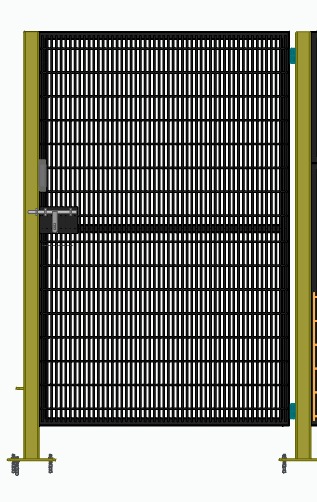

- Safety distance & access point validation

- Mechanical guard strength & integrity check

- Speed monitoring & safe-stop function validation

- Review of safety documentation and certifications

Benefits of Machine Safety Validation

- Ensures machine safety systems operate as intended

- Guarantees compliance with national & international safety standards

- Minimizes risk of accidents, legal issues & downtime

- Builds confidence for operators, auditors & regulatory bodies

- Improves reliability and lifespan of safety systems

Standards We Comply With

- ISO 12100 – Machine safety framework

- ISO 13849-1/2 – Safety control system performance

- IEC 62061 – Functional safety of machinery

- OSHA / IS local compliance standards