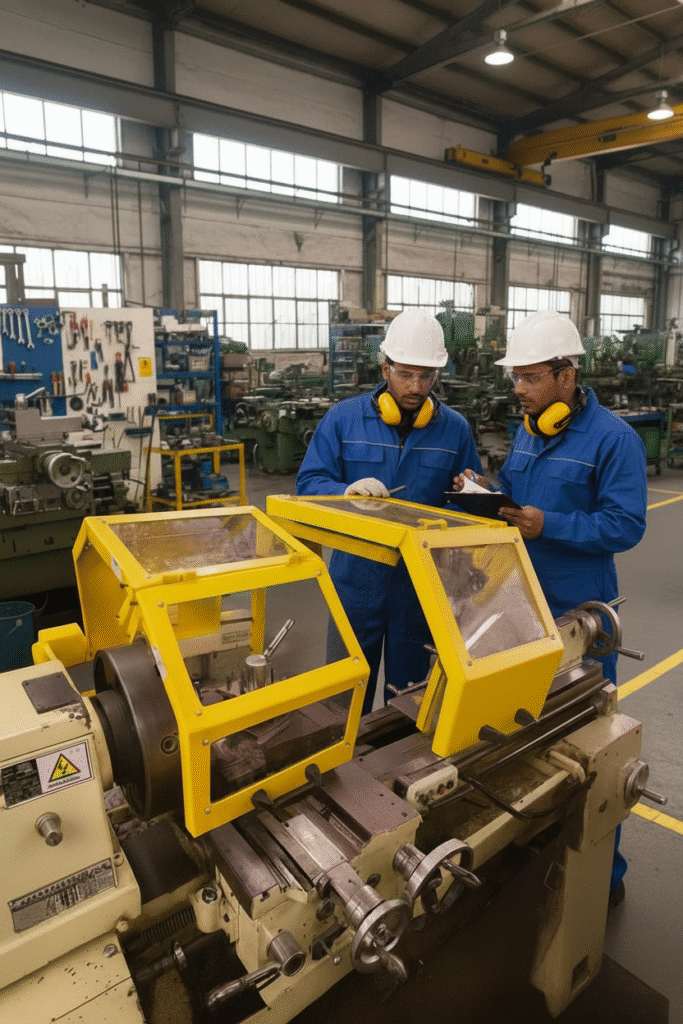

At PROTECTRASYSTEMS, we analyze every machine and production line to ensure compliance, prevent accidents, and improve operational efficiency. Our goal is to help you build a safer workplace while reducing downtime and enhancing productivity.

Our Risk Assessment Process

1.Verification & Training (Optional)

Ensure recommended controls are implemented and team is trained

2.Site Visit & Machine Study

Inspection of machine design, operation, and workplace layout

3.Hazard Identification

Detect potential injury risks during operation, cleaning, & maintenance

4.Risk Evaluation

Severity, exposure, and possibility of occurrence

5.Safety Controls Recommendation

Guarding solutions, signage, interlocks, PPE guidelines, safe operation methods

6.Documentation & Reporting

Complete risk matrix, compliance checklist, safety improvement plan

What We Assess

✔️ Mechanical hazards (moving parts, entanglement, pinch points)

✔️ Electrical safety & control systems

✔️ Access points, guarding & emergency stop systems

✔️ Operational hazards (start-up, shutdown, maintenance risks)

✔️ Human interface & ergonomics

✔️ Environmental factors (noise, dust, heat, proximity hazards)

✔️ Compliance with standards like IS/ISO, CE, OSHA

Why Machine Safety Risk Assessment Is Critical

- Protects workers from machine-related injuries

- Ensures compliance with OSHA, IS/ISO standards & factory safety regulations

- Reduces downtime, accidents, and compensation costs

- Optimizes machine performance through safer workflows

- Builds confidence during audits and certifications

Why Choose Us

- Industry-leading expertise in machine safeguarding

- Compliance with ISO/IS machine safety standards

- Tailored solutions for all industrial environments

- Fast reporting with clear, actionable recommendations

- Experience across FMCG, Automotive, Steel, Packaging, & Engineering industries